Inventory optimization is the process of managing inventory levels in a way that meets customer demand while minimizing costs associated with excess inventory. A lack of inventory optimization can lead to lost sales, missed opportunities, and decreased profitability. In this guide, we will explore the key components of inventory optimization, its importance, and how to effectively execute it in order to drive ecommerce sales.

How to Implement Inventory Optimization: A Step-by-Step Guide for Ecommerce Brands:

Understanding Inventory Optimization

Inventory optimization is a process of managing inventory levels to meet customer demand while minimizing costs associated with excess inventory. It involves forecasting demand, setting optimal inventory levels, and managing replenishment processes. According to a source, 75% of supply chain management professionals are willing to improve their inventory management practice.

Key Factors in Inventory Optimization

To effectively optimize inventory, marketers should consider various factors such as customer demand, lead times, supplier reliability, and inventory carrying costs. For instance, understanding customer demand is crucial in setting optimal inventory levels. Inventory carrying costs can be minimized by adopting a just-in-time inventory approach that allows for lower inventory levels and reduces storage costs. It is also important to monitor lead times and supplier reliability to ensure that inventory levels are maintained at optimal levels.

Inventory Optimization Techniques to Give You an Edge

Inventory optimization is a vital process for ecommerce retailers looking to maximize profits and minimize costs. The first thing to do when optimizing your inventory is to choose the right inventory management technique for your business. There are several techniques to choose from, and it's essential to select the ones that best suit your business needs. Here are some inventory management techniques to consider from:

Just-in-Time Inventory Management Technique

The just-in-time (JIT) inventory management philosophy involves stocking a product only when a customer requests it, thereby ensuring that inventory levels are proportional to the number of orders fulfilled. This approach was developed by Toyota and is known for providing significant cost savings. However, it is important to note that this strategy can be risky and should be implemented based on the specific industry and demand forecasting capabilities.

The primary advantage of JIT inventory management is that it minimizes the risk of dead stock, as inventory is only acquired when needed. This results in reduced storage expenses and a smaller warehouse footprint. To effectively manage inventory using this technique, it is recommended to utilize good facilities management software, which can assist in keeping track of inventory levels and other important metrics.

FIFO Inventory Optimization Method

First in, first-out (FIFO) is a method where the items received by a warehouse are dispatched to end consumers in the order they were received. It is commonly used in the food service or food supply industries, where products have a limited shelf life. However, any company can adopt the FIFO method if they want to avoid keeping items on hand for longer than necessary.

FIFO may not be suitable if the acquired items have variable pricing patterns as it may cause disparities between the cost of products received and the cost of items sold. Despite this, there are clear optimization advantages of using FIFO, particularly in reducing waste, especially for perishable foods. Additionally, it ensures that products are not kept for longer than necessary, optimizing warehouse circulation. In cases where certain batches of a product need to be set aside or certain machines are unavailable due to safety reasons, they can be marked with a Lockout Tagout system, which is a common practice in warehouses using the FIFO system and can be very helpful.

Predict Demand by Analyzing Historical Data

As a fundamental principle across all industries, a successful company is one that can accurately predict the future. To initiate demand forecasting, perform a detailed analysis of your historical sales data. Scrutinize your sales cycles, historical demand patterns, and lead times to gain a deeper insight into your inventory requirements. A profound comprehension of your sales cycles, historical demand trends, and lead times empowers you to make highly informed inventory management decisions.

Establish an Efficient Scanning System

It is advisable to scan products at every stage of inventory management, including receiving, moving, shipping, and any other alteration. Failure to implement a scanning system leaves your inventory vulnerable to inaccuracies resulting from human error or mistyped SKU numbers. This risk is particularly critical for eCommerce businesses that handle more SKUs in larger warehouses.

Using a good scanning system can help you accurately track your inventory in real-time, preventing stockouts and overstocks. By scanning products at every stage of the supply chain, you can keep track of the exact location of each item in your inventory, making it easier to fulfill orders and prevent delays.

Develop a Product Hierarchy using ABC Analysis

After establishing an inventory management philosophy, determining demand estimates, and setting data-supported par levels, it is important to categorize your product line using an ABC analysis. This technique involves classifying inventory into three categories based on their value and contribution to revenue: Category A for high-value but low-quantity items, Category B for moderately priced and moderate-quantity goods, and Category C for low-value but high-quantity items. Categorizing inventory in this way enables businesses to create customized restocking plans for each category, optimizing their fulfillment approach for each product line.

The ABC analysis helps you optimize your inventory by ensuring that you have the right amount of stock for each category of product, preventing stockouts or overstocks. It also helps you identify which products are contributing the most to your bottom line, allowing you to focus on optimizing those products.

Audit Your Supply Chain Continuously

It is recommended to conduct audits every six months to map out the components of the supply chain, assess their contributions, compare lead times and costs with competitors, and identify unfavorable trends such as consumer returns and faulty goods. Identifying defective links in the supply chain can prevent supply problems and facilitate inventory optimization efforts.

Cycle Counts

Regular and accurate inventory counts are crucial for efficient inventory management. However, traditional inventory audits that halt warehouse operations are outdated, dangerous, and inefficient. A more efficient and practical method is cycle counting.

Cycle counting is a technique that involves dividing inventory counting tasks among several days and staff members. Prioritize high-value items and have multiple workers count those products for a portion of their shift. Then move on to items in the B and C categories, which are counted more frequently. The frequency of your cycle counts is determined by how cautious you want to be in resolving inventory issues.

Cycle counting enables you to keep a close eye on inventory levels without disrupting day-to-day operations. Regular counts also help to identify discrepancies and address them before they become major issues.

Optimizing Inventory with Advanced Tools and Technologies

One of the most effective ways to optimize inventory is to leverage advanced tools and technologies. Automation can help streamline inventory management processes, making it easier to optimize inventory levels, reduce overstocks, and prevent stockouts. By using these tools, eCommerce businesses can gain a competitive edge and increase profitability.

One such tool is Pacvue, an inventory optimization platform that provides real-time inventory tracking, demand forecasting, and inventory management features. Pacvue also offers demand forecasting, which uses historical sales data to predict future demand, enabling businesses to optimize their inventory levels accordingly.

Other tools and technologies include automated replenishment systems, which automatically order new stock when inventory levels reach a certain threshold. This can help prevent stockouts and reduce overstocks, ultimately leading to increased profitability. Some inventory management systems also offer advanced analytics and reporting features, allowing businesses to gain insights into their inventory performance and identify opportunities for improvement. And this leads us to our next section.

Tools and Platforms for Inventory Optimization

There are numerous inventory optimization tools available in the market, each with its own set of features and capabilities. Here are four of the leading inventory optimization tools:

Pacvue

Pacvue is a leading ecommerce software solution that helps brands optimize their inventory across multiple marketplaces, including Amazon and Walmart. The platform provides advertisers with the ability to manage and optimize their eCommerce campaigns, with an inventory optimization tool that allows users to view inventory levels and forecast demand for products. Pacvue's tool also helps users identify which products are not selling, allowing them to make data-driven decisions to optimize their inventory.

Sellbrite

Sellbrite is another popular ecommerce software solution that helps brands optimize their inventory across multiple channels, including Amazon and Walmart. The platform offers an all-in-one inventory management system that allows brands to sync their inventory across all sales channels, automatically updating inventory levels and preventing overselling. Sellbrite also offers advanced reporting and analytics tools that help brands track sales performance and optimize their inventory levels accordingly.

Extensiv (Formerly Skubana)

Extensiv (formerly Skubana) is an ecommerce software solution that offers advanced inventory management and order fulfillment capabilities. The platform allows brands to manage their inventory across multiple sales channels, including Amazon and Walmart, with real-time inventory tracking and forecasting tools. Extensiv’s inventory optimization tool uses machine learning algorithms to predict demand and adjust inventory levels accordingly, helping brands minimize stockouts and overselling. Extensiv also offers advanced order management and shipping capabilities, making it a comprehensive ecommerce software solution for brands looking to optimize their inventory and streamline their operations.

Benefits of Inventory Optimization

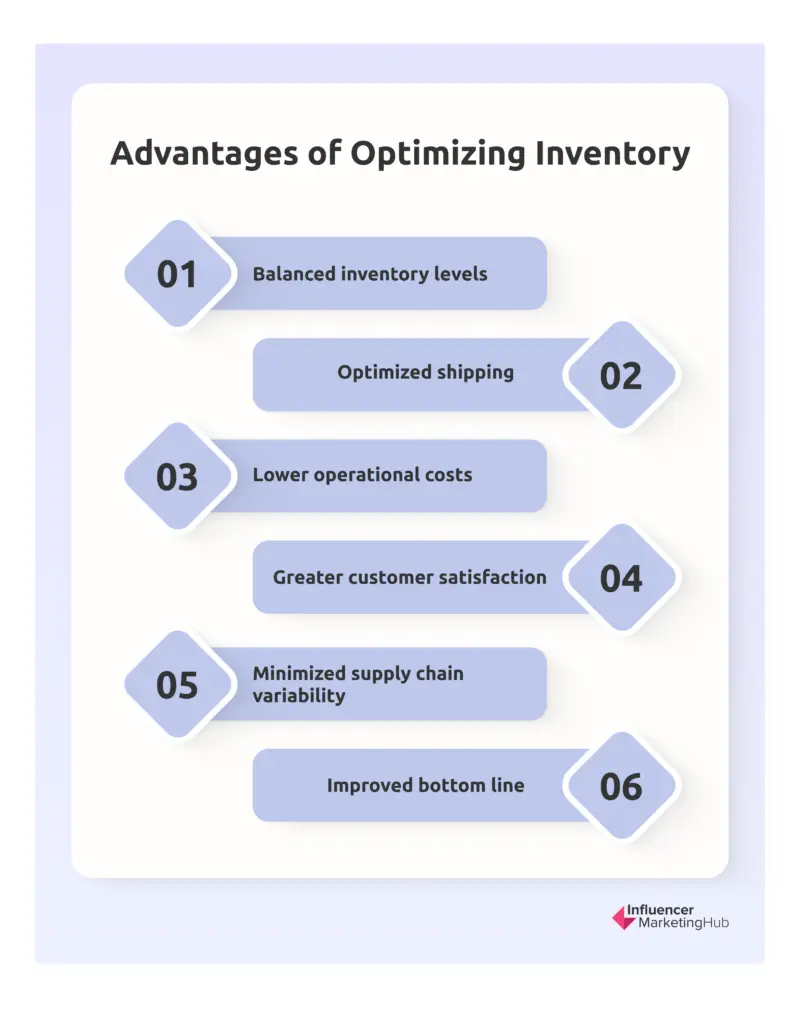

Inventory optimization is a critical practice for ecommerce retailers, as it offers significant benefits that can impact a business's bottom line. Here are six benefits that ecommerce experts should know about inventory optimization:

Balanced inventory levels

One of the primary benefits of inventory optimization is achieving balanced inventory levels. This means having enough inventory to meet demand while minimizing excess stock that can lead to higher costs and increased holding fees. Optimizing inventory levels ensures that retailers can accurately predict the demand for their products, reducing the risk of stockouts and missed revenue opportunities.

Optimized shipping

With inventory optimization, retailers can track their products in real-time across the entire supply chain. This allows them to move inventory to stock warehouse locations closer to areas with high demand, ultimately optimizing shipping and getting merchandise shipped out quickly and delivered on time. This results in satisfied customers who receive their products when they want them, ultimately leading to increased loyalty and customer lifetime value.

Lower operational costs

Inventory optimization can help retailers reduce their operational costs by eliminating excess inventory that is sitting in warehouses, which costs capital and raises holding fees. By carrying only the products that sell, retailers can reduce their operational costs and increase profit margins, ultimately impacting their bottom line.

Greater customer satisfaction

When retailers optimize their inventory, they always have the right products in stock, preventing stockouts and ensuring that customers can purchase and receive orders when they want them. This can lead to better customer experiences, improved loyalty, and increased customer lifetime value.

Minimized supply chain variability

By having balanced stock levels, inventory optimization protects retailers from unexpected supply chain disruptions, such as longer lead times and raw material shortages. Real-time inventory tracking enables retailers to quickly respond to supply chain issues before they impact their bottom line, leading to a more efficient and effective supply chain.

Improved bottom line

By optimizing inventory levels, retailers can improve their bottom line by reducing operational costs, increasing profit margins, and driving revenue growth. Inventory optimization flows through the rest of the business, improving key metrics such as cash on hand, gross profits, and consistent profitability.

Conclusion

In conclusion, inventory optimization is an essential aspect of ecommerce businesses that can lead to increased profits and improved customer satisfaction. By understanding key components, evaluating factors, and adopting best practices, businesses can effectively execute inventory optimization strategies. Additionally, businesses can leverage inventory optimization tools and platforms to automate the process of inventory management, demand forecasting, and supply chain management. As ecommerce businesses continue to grow and evolve, implementing effective inventory optimization strategies will become increasingly essential for success.

Inventory optimization is a process used by ecommerce retailers to optimize their inventory levels for maximum profitability. This involves forecasting demand, managing stock levels, and reducing costs associated with excess inventory or stockouts. Inventory optimization is critical for ecommerce retailers as it enables them to balance inventory levels, reduce holding costs, prevent stockouts, and ultimately maximize profits. By optimizing inventory levels, retailers can improve customer satisfaction, increase revenue, and drive growth. Ecommerce retailers can implement inventory optimization by analyzing sales data, forecasting demand, and adjusting inventory levels accordingly. They can also leverage tools and technologies like inventory management software to automate and streamline the inventory optimization process. The benefits of inventory optimization for ecommerce retailers include balanced inventory levels, optimized shipping, lower operational costs, greater customer satisfaction, minimized supply chain variability, and improved bottom line. Some inventory optimization tools available in the market include Pacvue, Sellbrite, and Extensiv (formerly Skubana), among others. These tools provide real-time inventory tracking, demand forecasting, and inventory management features that help ecommerce businesses optimize their inventory levels and reduce costs. Some common challenges that ecommerce retailers face when implementing inventory optimization include inaccurate demand forecasting, poor inventory management practices, and a lack of visibility across the supply chain. To overcome these challenges, retailers may need to invest in tools and technologies that enable them to optimize inventory levels and improve supply chain management. Frequently Asked Questions

What is inventory optimization?

Why is inventory optimization important for ecommerce retailers?

How do ecommerce retailers implement inventory optimization?

What are some of the key benefits of inventory optimization for ecommerce retailers?

What inventory optimization tools are available in the market?

What are some common challenges that ecommerce retailers face when implementing inventory optimization?